Recyl Ville-la-Grand, France, 31 May 2016

Pierre Chevreux, Founder-President of Recyl SAS, France and his fellow shareholders are pleased to announce that they completed the sale of Recyl to O&CG Holding SAS, owned by Charlotte and Olivier Goualard, effective June 1st, 2016.

Charlotte Goualard spearheaded R&D and Quality Engineering at Recyl over the past 9 years; initially ensuring the smooth transition and compliance to the REACH regulations, then progressively moving into R&D and building upon Pierre Chevreux’s savoir-faire. Charlotte’s work behind the scenes helped Recyl launch many of its latest products such as the QuickWash Flex, Clean Waterless or QuickWash Solvent PU ensuring Recyl’s continuous innovative character.

Charlotte’s husband, Olivier Goualard will take over the leadership of the company as Pierre Chevreux steps down and moves into a very well-deserved retirement. Olivier brings along a strong engineering and business administration background, as well as over 20 years of B2B and leadership experience in a multinational company.

Olivier Goualard said, “I’m thrilled to take Recyl forward, building on its excellent reputation in the domain of industrial printing. Recyl’s team combines experience and youth, expertise and innovation skills, and over all a real sense of customer service and an excellent team spirit, which allowed Recyl to build excellent partnerships with its customers, distributors and suppliers over the years. We are truly fortunate to have an extensive worldwide distribution & reseller network that helps us continuously support clients on every continent.”

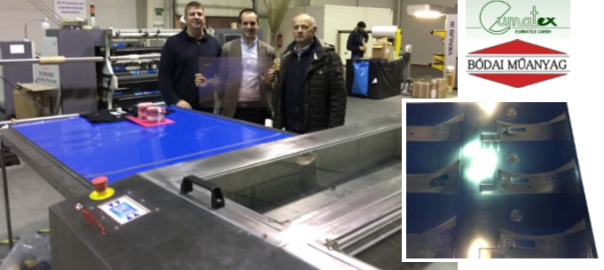

“The company is well-equipped to grow in the coming years; both in terms of new cleaning chemical products, more efficient and greener at the same time. In addition, at Drupa 2016, we are unveiling cutting-edge ultrasonic technology for Anilox maintenance. NextWave, Recyl’s latest ultrasonic range based on Sinaptec’s closed loop control system, gives us a crystal-clear advantage by guaranteeing cleaning results over time to its customers,” added Olivier Goualard, the new President of Recyl SAS, France.

Pierre Chevreux commented, “I’m happy to see that the future of Recyl is in good hands. Charlotte and Olivier Goualard combine together excellent technical and management skills, enabling Recyl to move forward in the complex and fascinating flexographic industry.”

About Recyl: Pierre Chevreux founded Recyl back in 1989, quickly creating strong demand for the Cobra, his special formula for deep cleaning of Anilox rolls, de-clogging ceramic rolls whatever the ink type or varnish. Over the years Recyl has established itself as a reference in the flexographic industry, as the company significantly extended its product range to a large choice of maintenance products and machines for Anilox, parts and plates, as well as its global reach through an wide network of distributors located all over the world.

Visit https://www.recyl.com for further details.

The Recyl Team will be in Hall 11, Stand C 32 at Drupa 2016.